The production rate and overall effectiveness of a die-casting factory are directly influenced by the quality of the mold used in the process. The die-casting mold is the essential component that underpins the production at the die-casting factory. The entirety of the die-casting industry has come to the conclusion that this is the case. The cavity dimensional accuracy, die-casting yield, die-casting production efficiency, mold reliability, mold life, and other factors all contribute to the overall quality of a die-casting mold. Die-casting plants' ability to compete and advance in the market is directly influenced by the quality of their molds. Only by increasing both the technical level of molds and their overall quality will it be possible to raise the standard of our die-casting industry as a whole.

Die-casting factories are required to have developed technical standards as well as specifics regarding their processing technology.

At the moment, the majority of die-casting factories, in general, do not pay sufficient attention to the process of mold manufacturing, instead concentrating their efforts on light processing and heavy assembly. In addition to this, the majority of them lack developed technical standards in addition to processing technology specifications. In practice, the master instructs the apprentice, and the master completes each step of the processing sequence solely based on their own personal experience. Additionally, there is not a reliable system for managing quality inspection, so the accuracy of the processed parts cannot be guaranteed.

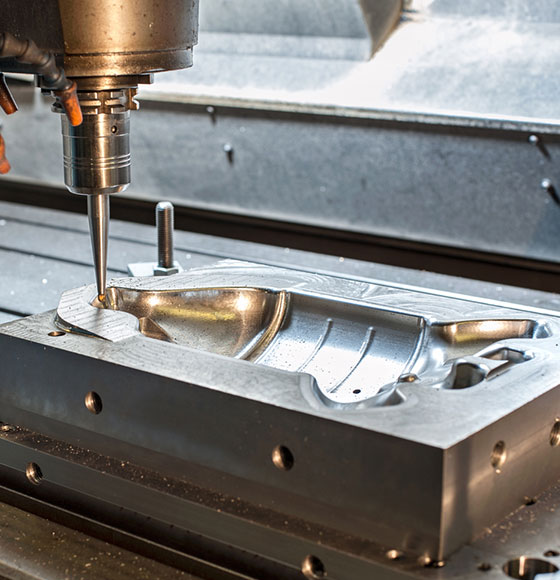

In this manner, assembly is required during the mold assembly process, and fitters are responsible for completing a significant amount of the work. Only an assembler, a good die-casting factory fitter is essential to the production process. Machining the mold to completion ensures its accuracy, which is then checked die casting company against both the company's technical standards and the specifications that were provided. In addition to this, one of the primary reasons why our die-casting plants have an excessive number of fitters is because of this factor. As a result, in order to raise the quality of our mold, we will need to modify our concepts. Die-casting factories have a duty to focus on the manufacturing process, its associated technology, and the quality control of the manufacturing process. Manufacturing facilities that use die-casting must develop mature and efficient technical standards and processing technology specifications.

Management of an enterprise ought to involve a wide variety of facets and links, such as technical management, quality management, safety management, equipment management, human resources management, on-site management, cost management, and so on. Standardized management, which can also be described as programmed, institutionalized, standardized, and orderly management, is essential to the management of modern businesses. Even though the proverb "three points technology, seven points management" might not be entirely accurate, the fact that it exists demonstrates Powder Coating Cast Aluminum how management is one of the most crucial aspects of any enterprise. It ought to go without saying that management is the cornerstone upon which an organization is built and grown. Therefore, our die-casting factory should learn from advanced foreign companies, beginning with management, focusing on every link, standardizing management, establishing a sound management system, and significantly improving both the level of corporate management and the quality of molds.

Die-casting molds should be brought up to a higher technical level.

Reinforce the particulars, integrate them with the actual die-casting production, and enhance the quality of the die-casting molds. Based on the current state of domestic die-casting plants, it appears that more consideration is given to the pouring and drainage system of the mold as well as the size of the castings, but not nearly as much consideration is given to the reliability of the mold, the qualification rate of the castings, or the life of the mold.Despite the fact that in recent years, the equipment level of die-casting plants has been improving, high-precision testing equipment has been introduced, and design and processing software has been applied, the accuracy of mold processing has generally improved.Insufficient attention and research on layout and other aspects, particularly the insufficient review of the details of the mold during the development stage, and the details are not done in place, which results in frequent problems when using the mold, low efficiency, or low yield, which seriously affects the die casting factory production efficiency and quality.

Because of this, we need to combine the actual die-casting production, carefully carry out the preliminary review of the mold, and raise the bar for the level of mold design.It is necessary to combine the production of die-casting molds with die-casting production in order to improve the quality of die-casting molds.The dependability of the die-casting mold is an extremely important factor to consider.Due to the unique characteristics of die-casting, the repair or replacement of a defective die-casting mold will result in astronomically high costs.Therefore, it is necessary to ensure the strength of the die-casting mold and ensure the reliability of the mold when designing and manufacturing die-casting molds. This is because the die-casting mold is what will be used to cast the metal.Do not compromise the reliability of the mold in order to save a few dollars because the gain will not justify the loss.

Die-casting costs can be reduced in significant ways, one die casting defects causes and solutions of which is by increasing the mold production efficiency.We need to pay attention to the internal cooling of the mold, avoid using external spraying as much as possible to solve the problem of mold temperature balance, reduce the amount of spraying, reduce the amount of time spent spraying, and reduce the amount of time needed for the casting to cool on the mold. This will allow us to improve the die-casting production rhythm. Die-casting molds absolutely require internal mold cooling in order to function properly. Because the quality of the die-casting parts' internal mold cooling has not only an effect on the efficiency of production but also a significant influence on the parts' overall quality.

Improve the quality of the molds by utilizing modern mold technology

With the advancement in technology and management level of die-casting plants, in particular the widespread adoption of automated die-casting production in many die-casting plants, a large number of new technologies and processes have been continuously adopted in recent years. These technologies and processes include high-pressure cooling, local pressurization, vacuum die-casting, etc. etc. As a result, the requirements for die-casting molds are becoming more stringent with each passing year.As a result, die-casting factories need to increase the amount of effort they put into the research, application, and improvement of new die-casting mold technologies, as well as the quality of their molds.

Pay close attention to the design details of the mold in order to increase the efficiency of the die-casting production process. This includes accelerating the rate at which the mold can be disassembled and reassembled, lowering the amount of time spent on mold repair and maintenance, and shortening the amount of time required to replace wearing parts. For instance, a two-level oil cylinder is used to cut down on the amount of time needed for the core pulling process; the core and other wearing parts are easily replaced, which eliminates the need to disassemble the mold in order to replace it, which boosts the efficiency of the die-casting production process; the oil pipe, travel switch, and joints are connected to the mold in order to be used with the press; and finally, the die-casting press is used in conjunction with the mold. When the clamping is done quickly, loading and unloading the mold takes a significantly shorter amount of time.