How To Fix LED Strip Lights When Cut

Have you ever experienced the frustration of dealing with malfunctioning LED strip lights? It's a frequent situation where the LED lights unexpectedly go dim or the entire strip using LED lights stops functioning altogether. This article will explore the process of troubleshooting and fixing a malfunctioning LED strip with LED lights.

In this blog post, we will explore the underlying factors responsible for a malfunctioning LED strip with LED lights and walk you through the necessary steps to address the problem. Furthermore, we will also address the potential risks associated with attempting DIY repairs on your LED strip illuminated by LED lights.

5 Reasons that Causes Broken Led Strip

Handle with Care: When installing LED strips, remember that these lights are delicate. Accidental contact or obstruction during other tasks can lead to solder joint failures. Over-bending or deforming the strip can result in a once functional LED strip that no longer lights up.

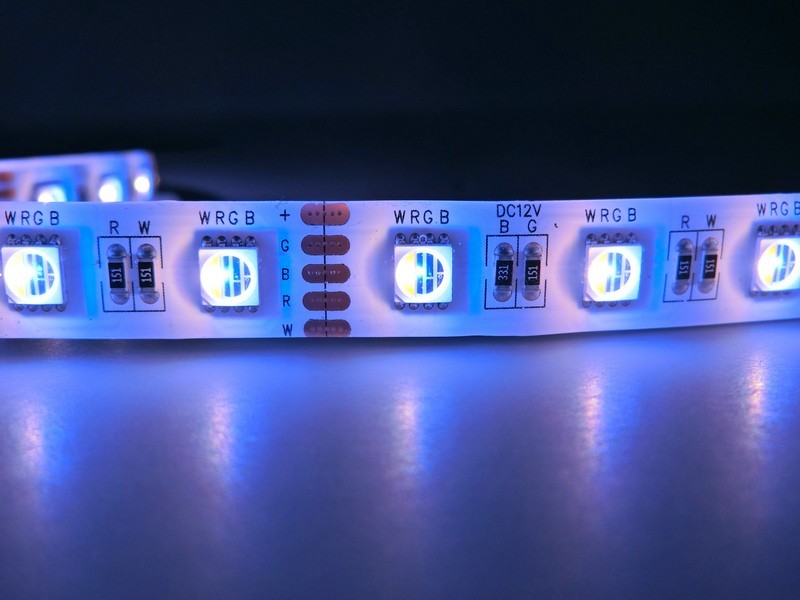

Check Connections: Ensure that the connections for your LED strip have good contact. Poorly connected joints can disrupt the flow of electricity. When troubleshooting a non-working strip, start by verifying the integrity of the solder joints. Look out for cold solder joints or areas where the copper doesn't appear bright and shiny.

Avoid Over-Bending: Repeatedly bending the solder joints can lead to fatigue and connection failures. Be cautious with excessive bending, especially if the strip isn't on a flat surface, as it could damage the contacts inside the waterproofing sleeve. Additionally, excessive friction and heat from bending might cause scratches or dents in the insulation, leading to circuit shorts.

Guard Against Water Damage: Water entering the LED strip can cause the internal electronics to short out or corrode. Before powering on a new LED strip, ensure that all connections are dry. Keep in mind that even after drying, corrosion issues could develop over time.

Wiring Correctly: Incorrect wiring, such as connecting the LED strip in reverse polarity, can cause problems. The power supply's negative and positive leads have different resistances, and if the LED strip is wired improperly, the batteries may only charge to a specific voltage. Be attentive to proper wiring to avoid issues.

Temporary Fixing Steps:

Step 1: Measure and Cut

Start by measuring the length of the torn or damaged section on your LED light strip. Cut another piece of the same size from a flexible, waterproof silicone tube.

Step 2: Seal and Protect

Place the new silicone tube piece on top of the torn area, ensuring proper alignment. Use a soldering iron to seal the edges securely. Make sure to seal the ends of the silicone tube thoroughly to prevent water damage to the LED strip.

Step 3: Knot and Secure

Tie a knot around the silicone tube and the LED light strip, ensuring it's tight but not too tight. This knot will help the repaired section stay in place after insertion.

Step 4: Solder the Wire

Reconnect the wires that were separated due to the damage. Carefully solder them back together. Gently push the silicone tube down so that the LED light strip fits snugly into its original position.

Step 5: Test the Repair

Plug in the LED light strip to ensure it functions properly. Check that the repaired area hasn't caused a short-circuit or other issues.

Step 6: Secure with Waterproof Adhesive

If the LED strip lights are operational, employ a waterproof adhesive such as hot glue or silicone glue to reattach the LED strip lights securely. This guarantees the strip lights remain firmly in position, even when faced with varying weather conditions, thus safeguarding their functionality and lifespan.

Permanent Fixing Steps:

Step 1: Remove Silicone Tube

Begin by carefully cutting off the silicone tube from both ends of the LED light strip. This provides more room to work without the risk of short-circuiting the entire strip.

Step 2: Solder the Wires

Use a soldering iron to reconnect the two wire pieces that were separated. Make sure to achieve a secure and reliable connection.

Step 3: Reattach to PCB

Carefully reattach the two wires back into their solder joints on the PCB (Printed Circuit Board). Ensure a snug fit and use the soldering iron to secure them in place.

Step 4: Protective Wrap

Apply a piece of electrical tape around the outside of the joint to provide protection against future short-circuiting.

Step 5: Test the Repair

Before proceeding, test the repaired LED strip to ensure proper functionality. Connect it to a power source, and if you have multiple strips, check that all of them work when daisy-chained.

Step 6: Heat Shrink Tube

Cut a piece of heat shrink tube large enough to cover the electrical tape on both sides of the joint. Carefully slide the heat shrink tube over the taped area and use a heat gun or blow dryer to shrink it down securely.

Step 7: Create Notch Holes

Create notch holes on each side of the strip, allowing access to mounting screws. Wrap the joint with silicone-based electrical tape to prevent future short-circuiting.

Step 8: Mount the LED Strip

Now that the repair is complete, you can mount the LED strip in your desired location. Use screws and drywall anchors to securely fasten it in place, whether it's under a desk or along a wall. This ensures a permanent and stable installation.

Conclusion

Should you encounter a broken LED strip, worry not! This troubleshooting guide is here to lend a helping hand. By following these straightforward steps, repairing your LED lights will become a breeze.

Equipped with the right knowledge and tools, the days of dealing with lifeless or flickering LEDs are over!

We firmly believe that this extensive guide has provided valuable insights into effectively repairing malfunctioning LED light strips. Should you require additional clarification, feel free to contact us directly or leave a comment below. Our team is readily available to offer assistance and resolve any inquiries you might have. For the best LED light strips options, don't hesitate to explore our selection as well.