Although humans have been using tools to harness and amplify energy for 2.6 million years, the true development of machining came with the Industrial Revolution.

The Industrial Revolution began in the 18th century and was a reform of the machining industry. With the advent of machines, potential productivity increased dramatically, while production time was drastically shortened. During this time the employment rate in factories rose, as did the length of working hours. It was not until 1833 that the Factory Act imposed a limit on working hours for children, setting a standard for factory work and subconsciously noting recognition of the level of human demand. The Factory Act prompted manufacturers to seek options that reduced the need for human input, thereby paving the way for automated processing methods.

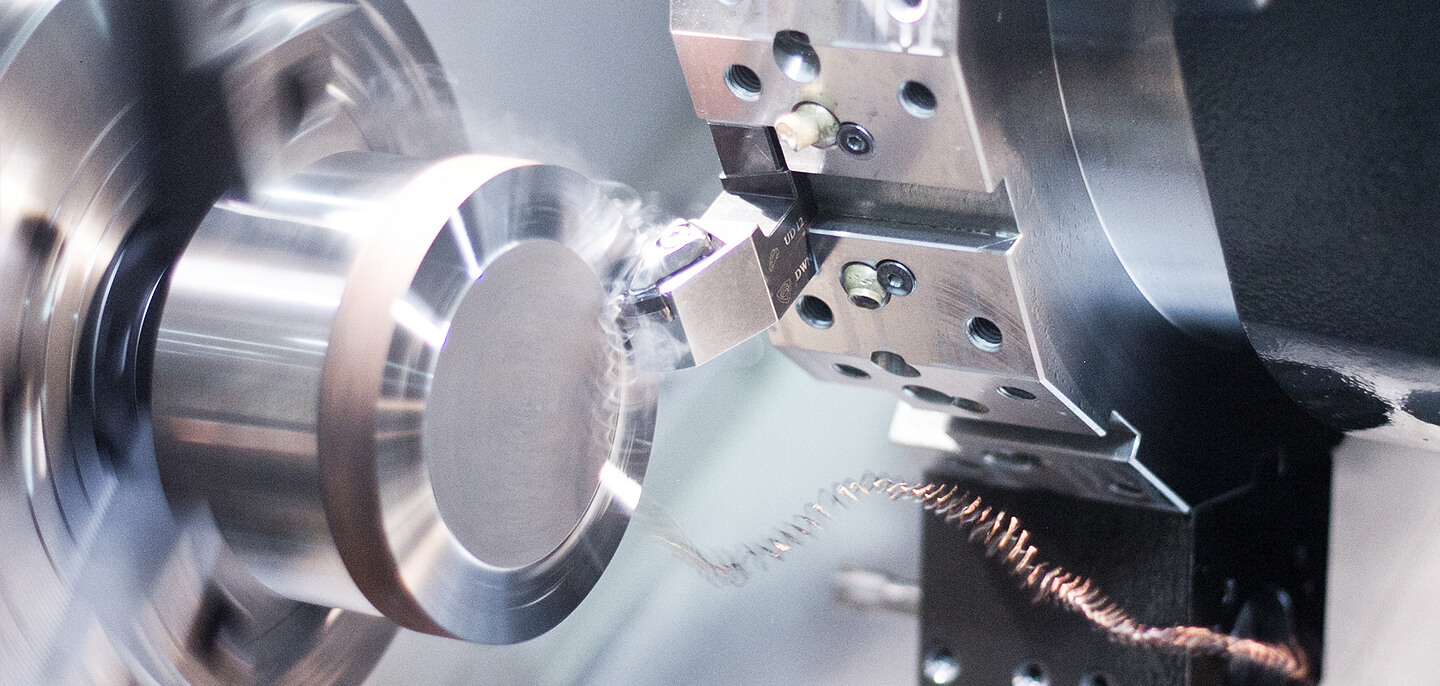

The evolution of CNC machines

The introduction of digital technology in the 1960s and 1970s made numerically controlled machine tools more like the ones we use today. This marked the evolution from punching tape to digital software, which operates on the same principles as CNC machining but has more room for technological advancement. The software that replaced punched tape is called CAD (Computer Aided Design) software and, after some updates and upgrades, is what we use today. CAD software allows people to create a drawing on a computer that is translated into a human-readable format with a CNC called G-code that guides the machine tool to work on specific axes and movements. CAD software allows for faster production of designs and the ability to make endless changes and updates to the software, ensuring that CNC machining is a sustainable and future-proof production investment.